ZHEJIANG JINGDUN TECHNOLOGY CO.,LTD.

Main technical parameters

| Parameter table | ||

| Maximum turning diameter on bed | mm | Φ 360 |

| Maximum turning diameter of the carriage | mm | Φ 180 |

| Maximum Z-direction travel | mm | 355 |

| Maximum X-direction travel | mm | 480 |

| Fast moving speed | m/min | X:30 Z:30 |

| Diameter of spindle through hole | mm | Φ 48 |

| Spindle motor power | kw | 5.5 frequency conversion |

| Spindle speed | rpm | 200-3000 |

| Cross sectional area of cutter bar | mm | 20*20 |

| Torque of motor in X direction and Z direction | nm | X:7.7 Z:7.7 |

| Connection mode of x-direction and Z-direction motors | Direct connection | |

| Specification of x-direction and Z-direction screw rod | X:3210 Z:4010 | |

| X-direction and Z-direction ball track specifications | X:30 Z:35 | |

| Spring collet specification | Φ 56 chuck / M48 tube | |

| Chuck specification (optional) | mm | Φ 200/ Φ 160 |

| Taper of tailstock sleeve | mt | NO.4 |

| Repeat positioning accuracy | mm | 0.003 |

| Positioning accuracy (machine tool accuracy) | mm | 0.01 |

| Cooling water pump power | W | 120 |

| Machine weight | kg | ≈2000 |

| Machine tool dimensions (L * w * h) | mm | ≈2150*1650*1750 |

Main configuration

| Main configuration |

| Beijing kaienti bus absolute value servo system (or Taiwan new generation) |

| Resin sand casting (domestic) |

| Spindle (made in China or Taiwan) |

| Ball screw (made in China or Taiwan) |

| Automatic lubrication system (made in China) |

| Special bearing for screw rod (imported) |

| Linear guide (Taiwan) |

| Pneumatic clamping (or hydraulic clamping and chuck clamping) |

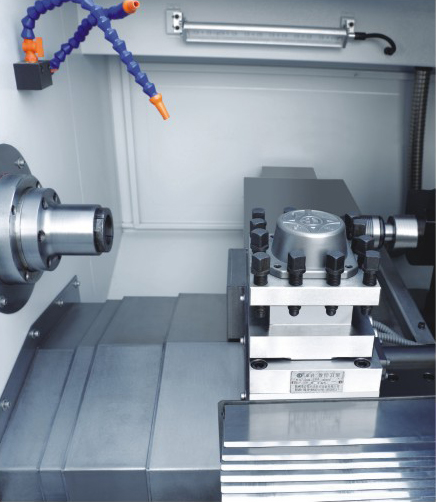

| Four position electric turret + row turret |

| Main motor (domestic four pole motor) |

| Main electrical components (Schneider) |

| High rigidity hard rail tailstock (manual / pneumatic / hydraulic optional) |

| It can be selected according to the needs of users |

Local display